PRODUCT CENTER

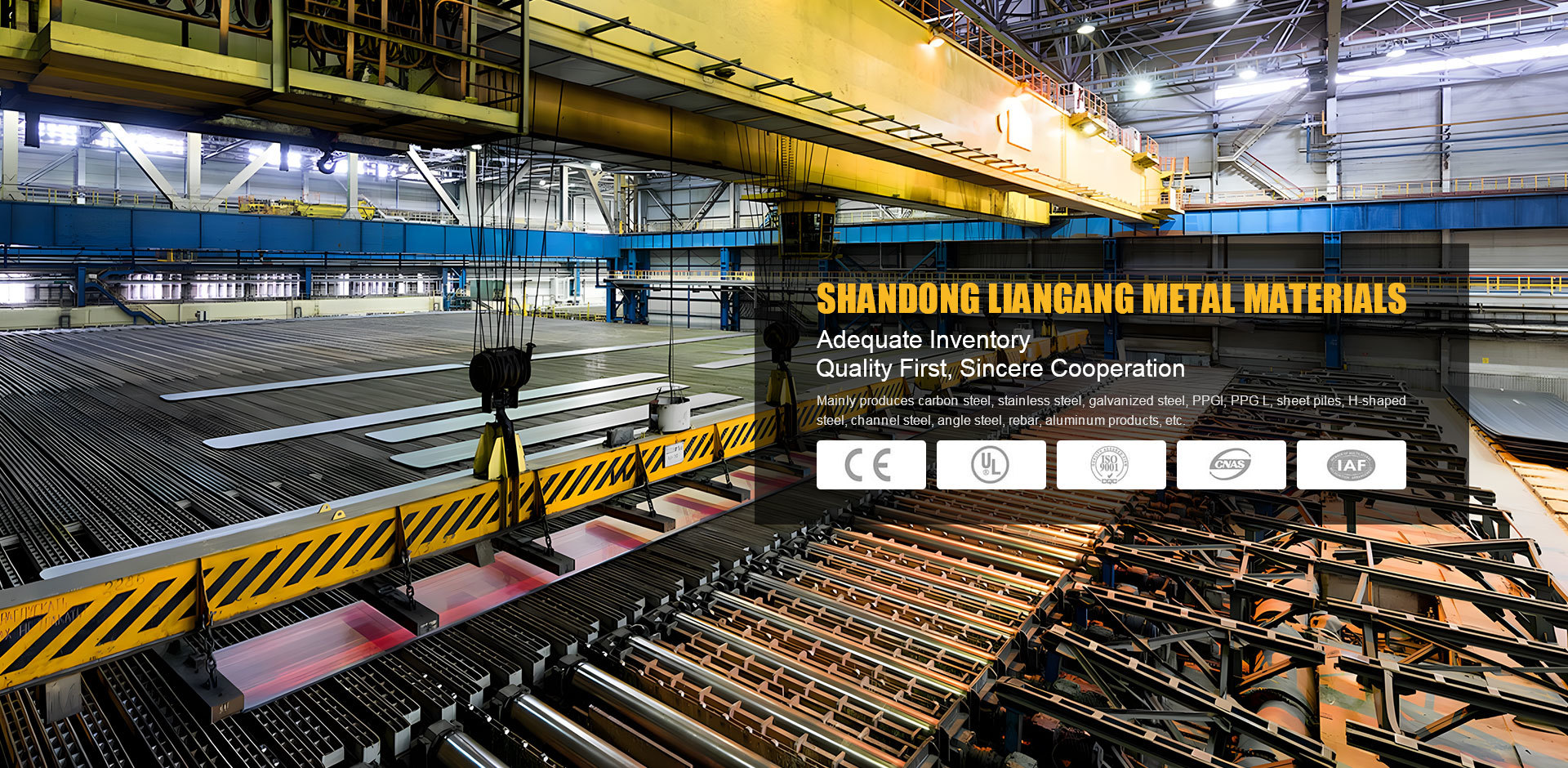

Mainly produces carbon steel, stainless steel, galvanized steel, PPGI, PPG L, sheet piles, H-shaped steel, channel steel, angle steel, rebar, aluminum products, etc.

ASTM A588 steel includes Class A, Class B, Class C, and Class K. The ASTM A588 steel specification is based on the standard specification for high-strength low-alloy structural steel with a lower yield point of up to 50ksi for applications requiring high strength and corrosion resistance.

Stainless steel angle steel can be composed of different force components according to the different needs of the structure, and can also be used as a connector between components. Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves. Stainless steel angle steel is a carbon structural steel for construction. It is a simple section steel, mainly used for metal components and plant frames. In use, it requires good weldability, plastic deformation performance and certain mechanical strength. The raw material billet for the production of stainless steel angle steel is low-carbon square billet, and the finished stainless steel angle steel is delivered in hot-rolled forming, normalizing or hot-rolled state.

A36/Q235/S235JR Carbon Steel Coil

A36 is a low-carbon steel containing trace amounts of manganese, phosphorus, sulfur, silicon and other elements such as copper. A36 has good weldability and high yield strength, and is the structural steel plate specified by the engineer. ASTM A36 steel plate is often manufactured into a variety of structural steel parts. This grade is used for welded, bolted or riveted construction of bridges and buildings, as well as for general structural purposes. Due to its yield point, A36 carbon plate can be used to design lighter-weight structures and equipment, and provide good weldability. Construction, energy, heavy equipment, transportation, infrastructure and mining are the industries where A36 panels are commonly used.

A179 seamless cold drawn low carbon steel pipe is equivalent to China's No. 10 high-quality low-carbon steel. A179 is suitable for cold-drawn high-quality low-carbon seamless steel pipes for heat exchangers and condensers.

A36 is a low-carbon steel containing trace amounts of manganese, phosphorus, sulfur, silicon and other elements such as copper. A36 has good weldability and high yield strength, and is the most specified structural steel plate by engineers. ASTM A36 is most commonly manufactured as a variety of structural steel parts. This grade is used for welded, bolted or riveted construction of bridges and buildings, as well as for general structural purposes. Due to its lowest yield point, A36 can be used to design lighter-weight structures and equipment, and provide good weldability.

202 stainless steel is an austenitic chromium-nickel-manganese alloy. It has high ductility, good corrosion resistance and excellent toughness in both high and low temperature environments. 202 stainless steel is one of the most widely used 200 series stainless steel. 202 stainless steel, the austenitic structure is stabilized by the addition of nickel and manganese, thereby preventing the formation of harmful phases, such as sigma phase or chromium carbide. The high nickel content also improves the corrosion and oxidation resistance of the steel at high temperatures.

A213 Seamless Carbon Steel Pipe

ASTM A213 designates grades T5, TP304, etc. Grades with the letter H have a higher creep rupture strength than grades without H. ASME SA213 seamless pipe is chrome molybdenum alloy pipe. ASTM A192 is the same as ASME SA-192 and is the standard specification covering seamless carbon steel boiler and superheater tubes of minimum wall thickness for high pressure service.

Hot-dip galvanized channel steel is also called hot-dip galvanized channel steel and hot-dip galvanized channel steel. It is an effective metal anti-corrosion method and is mainly used in metal structural facilities in various industries. It is to immerse the channel steel after derusting in the molten zinc of about 440~460 ℃, so that the zinc layer is attached to the surface of the channel steel, thus achieving the purpose of anti-corrosion. Now the main method of galvanizing the surface of the channel steel is hot dip galvanizing.

20 years of experience

Annual Production Capacity

Active Employees

Annual Sales 200 Million

SHANDONG LIANGANG METAL MATERIALS CO., LTD.

Shandong Liangang Metal Materials Co., Ltd. is located in Jinan, the capital of Shandong Province. It is a company integrating production, processing, sales and transportation. Mainly produces carbon steel, stainless steel, galvanized steel, PPGI, PPG L, sheet piles, H-shaped steel, channel steel, angle steel, rebar, aluminum products, etc. We have our own processing plant and inventory warehouse, which can provide customers with various customized services such as galvanizing, color coating, leveling, slitting, straightening, and pressing. We are committed to meeting the diverse customization needs of our customers.

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

APPLICATION AREAS

Steel is also widely used in the manufacturing industry. It is used to produce various manufacturing equipment such as automobiles, trains, ships, agricultural machinery, heavy machinery, etc. Steel has high strength and wear resistance and is widely used in the manufacture of high-strength parts such as mechanical parts, bearings, gears, etc.

Chemical Plant

Pipeline Transportation

Ocean Exploration

Steel Structure

Shipyard

NEWS CENTER

We have our own processing plant and inventory warehouse, which can provide customers with various customized services such as galvanizing, color coating, leveling, slitting, straightening, and pressing. We are committed to meeting the diverse customization needs of our customers.

May 13,2024

The difference between steel coils and steel strips

May 13,2024

May 13,2024

May 13,2024